Energy Efficiency

Energy Efficiency

Do you think that the design of your thermal processes and equipment is regularly challenged when your fuel consumption is excessive? Was energy efficiency a priority at the time of their design? Have your thermal equipment been designed with a view to overall efficiency of your entire process? Otherwise, there are certainly avenues for optimizing and reducing energy consumption of your thermal processes and equipment.

With Valtech Energie's team, you benefit from proven expertise for the analysis of the energy efficiency of industrial processes. Since 2011, Valtech Energie has successfully participated in meeting the challenges and issues that our customers face.

If you are looking for an engineering firm on which to rely in your approach to reduce your energy consumption, here are the types of services that we offer:

- Identification and quantification of your potential for lower consumption.

- Profitability evaluation of identified energy efficiency projects, with and without available financial assistance.

- Design and implementation of energy performance and consumption monitoring tools, including savings calculations for potential and realized energy optimization projects.

- Technical assistance for the implementation of an energy management system for your process or your factory, according to the criteria of certification to ISO 50001.

Because the needs of each plant are distinct, we adapt our services to each of our customers.

What sets us apart in the thermal analysis of your processes:

The specific consumption of a process makes it possible to predict its total consumption as a function of a given production volume. Theoretically, as the volume of production increases, the specific consumption decreases, assuming the fixed charges remain constant.

The adjacent graph presents the energy balance of a high temperature furnace. We can distinguish the following:

- Useful power, which is the energy transferred to the product. This amount of energy is proportional to the volume of production.

- Losses through the walls, which are fixed.

- Smoke losses which are proportional to the power absorbed.

- Losses by incoming air or air infiltration which represent 37% of the absorbed power. Depending on the process, and with the establishment of adequate control, these losses can be reduced to around 5%.

It is by carrying out such assessments that we can characterize the consumption and energy savings of your processes, tailored to the fluctuation of your production.

If you want to have a precise analysis prior to investing in the energy optimization of your process, the characterization of your consumption is a necessary condition, but it must be based on reliable data provided by measuring instruments. The use of energy balances allows, by crossing theoretical data and measured data to validate its data and to intervene in the event of:

- Malfunction of measuring instruments;

- Malfunctions of thermal process equipment.

Once the data provided by the measurement has been validated, the process of evaluating the optimization potential can be undertaken:

- Calculating energy and financial gains;

- Rengineering partially or totally high potential equipment;

- Calculating project implementation costs;

- Calculating financial profitability of projects;

- Prioritizing identified optimization projects;

- Identifing potential for cross-impact between projects;

- Identifing performance indicators.

In comparison to the rest of North America, Quebec offers one of the best financial assistance for the development of energy efficiency projects.

More concretely, financial assistance is availbale for the implementation of projects, that can cover up to 75% of investments, with a cap of $ 5,000,000 per project. The amount of this aid is proportional to the greenhouse gas emissions avoided, over a period chosen by the beneficiary that can range from 1 year to 10 years. This aid ofen reduce reduce the Return on Investment Period (ROI) of major projects from over 5 years to less than 2 years, does not deprive the beneficiary of his carbon credits with the SPEDE.

For carrying out energy efficiency studies, an assistance of $ 25,000 is available, which covers 50% of internal and external costs. Depending on your consumption of natural gas, this assistance can be uncapped up to $ 50,000.

For more information, you will find tables describing the financial assistance available in Quebec and in the rest of Cananda at the bottom of our “Energy Efficiency” page.

The services we provide during the process of implementing energy efficiency projects are always eligible for the financial assistance presented above.

For companies based in Québec that want to move up a gear in terms of reducing greenhouse gas (GHG) emissions, it is possible to implement an internal energy management program. In this framework, you can benefit from a grant covering 50% of the cost of the following processes:

- Development of an implementation plan for measuring instruments in your plant;

- Identification of key data to detect possible drifts in the performance of your equipment;

- Implementation of an energy management system.

The subsidy associated with these benefits, for which we can support you, is capped at $100,000.

The implementation of an energy management system may require the use of measuring instruments and digital data storage devices. This equipment, which has seen its purchase cost reduced, is the subject of financial assistance of 50% of its installation cost, up to a limit of $150,000.

Often overshadowed by energy analyses and energy projects, an internal energy management program is the surest way to prioritize projects and manage the interactions efficiency projects can have with each other.

Some processes involve heating and cooling the fluids used for production.

This leads to an abundance of energy reduction potential, by exploiting the fluids to be cooled to heat others and vice versa.

Pinch analysis allows you to select the best energy recovery opportunities by identifying the pairs of fluids to select for optimal energy transfer.

The Pinch analysis looks best when it is applied in the chemical industry for which it was originally developed. There is a potential for using this method in certain processes in the food sector where production fluids are alternately heated and cooled.

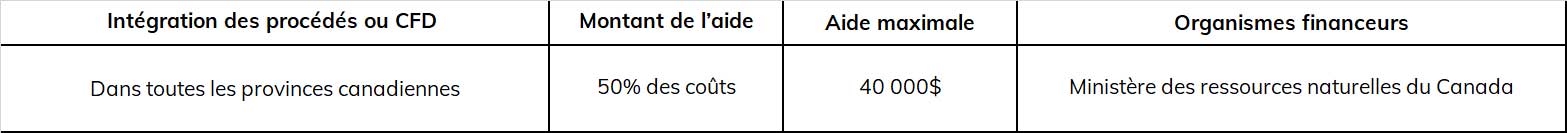

The completion of a Pinch analysis may be subject to financial assistance of $ 40,000 which covers 50% of the costs incurred internally and externally.

Financial assistance program in Quebec and Ontario for the development of energy efficiency projects

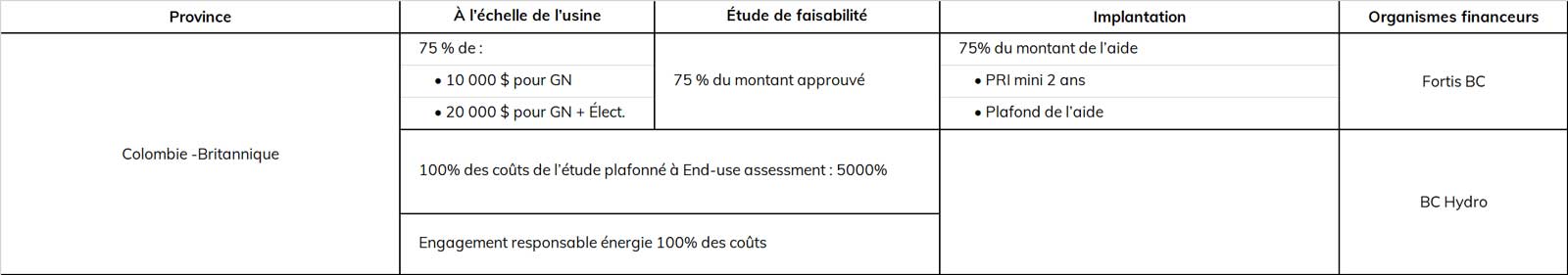

Financial assistance programs for the rest of Canada for energy efficiency projects

Relevance of a continuous energy performance monitoring tool

The measurement of fuels supplied to processes and factories is the best way to have reliable data on their energy efficiency.

When these flow rates are variable, depending on different parameters (mass, product quality, climatic conditions, etc.), the measurement of fuels must be accompanied by the measurement of additional data. The interpretation of this data is only possible using mathematical processing.

These calculations can be performed manually or by the controller (PLC/DCS) which collects and records the digital data supplied by the measuring instruments. Depending on the nature of the calculations to be made, the programming of the controllers can be cumbersome, and require costly investments. This is due to the fact that these are primarily designed to automate the control of equipment.

As an alternative to this option, we have developed a continuous data processing tool, whose calculations and storage are performed on Excel, installed on a PC.

This approach makes it easy to integrate tables of physical properties (saturated steam), or other types of tables related to the properties of raw materials. This makes it possible to develop mass and energy balances in real time, and to continuously validate the accuracy of the instrumentation used.

Consult us on the implementation of your performance monitoring tool.